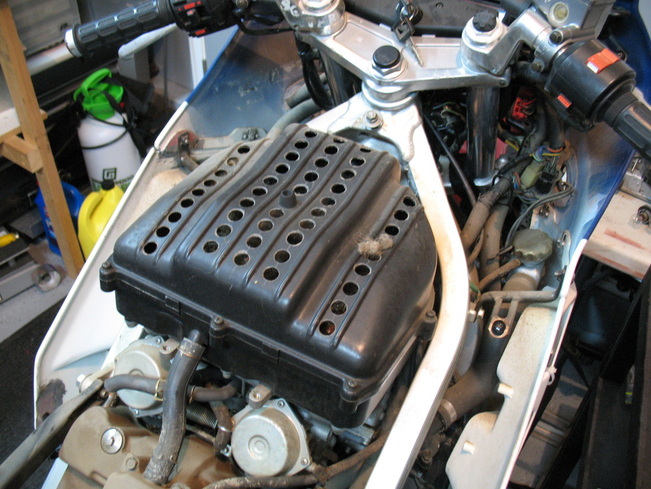

Once the valve check is finished (only four in need of adjustment), the compression is measured. A proper compression check involves a warmed up engine, but most of my projects aren't so fortunate and I have to settle for a cold check on cylinders/valves that may not have been run for years. Still, any compression check is a good indicator of major internal engine issues and so is a must-do. Project 19 does well with all cylinders reading between 140-150.

This is a fairly common problem with this era of Japanese bikes and Hondas are not exempt. As late as 2005 Honda had to issue a VFR800 recall for this sort of thing.

The problem stems from a bad R/R design and is way more complicated than my analog brain can follow, but the real fix is a better R/R, like Rick's (http://ricksmotorsportelectrics.com). This particular bike has an unknown replacement R/R in place so I elected to make the repair and test the charging system later when the bike is up and running.

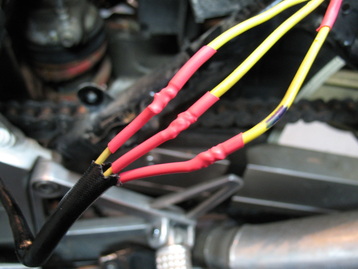

And here's my repair. No high-resistence connectors for me. Nope. Hardwire the stator leads with a solid soldered joint. Leave as much excess wire as possible so a future repair can be easily done.

NOTE: The three yellow wires are not particular about their partners — they can be reattached to any one.

After individually wrapping the joints, the entire length is taped and tucked into place. Job done.

All that's left is to mount up a carb set, top off the coolant, fire the engine and see if the electrons are moving as they should.

RSS Feed

RSS Feed