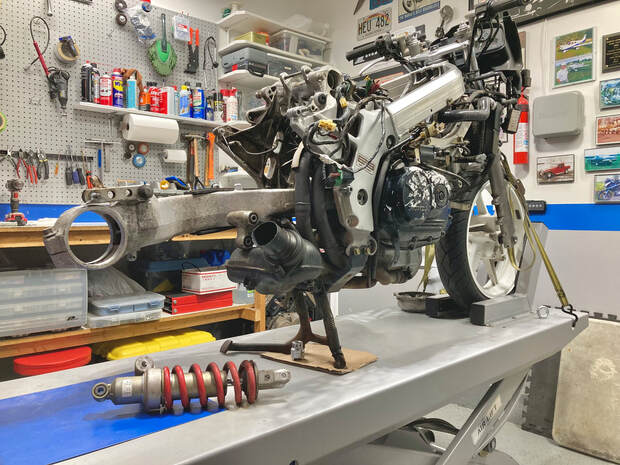

Several of my projects have suspension modifications, from mild to more complex. A basic component of suspension is the spring, and is probably the most modified of suspension parts. When we change out the spring, it's nearly always to change the spring rate.

So what does spring rate mean? In simple terms, a 1.1kg/mm spring, for example, means that it will require 1.1 kilograms (2.4 pounds) of force to move the spring one millimeter. Straight-wound means that the spring has a constant resistance throughout its movement — each additional millimeter of movement requires an additional 1.1kg of force. A true "progressive" or "dual-rate" spring will have less resistance in its initial travel and greater resistance as it compresses. This would theoretically be ideal in a street application, so as to allow small bumps to move the fork or swingarm more easily (less jarring) but then resist large bumps to prevent bottoming. In practice, however, this isn't completely practical for the relatively short fork/shock travel common to street motorcycles, but is very useful in the off-road world with their long-travel suspensions. Soft initial travel also promotes undesirable fork dive under braking. In fact, road racing bikes will almost always have straight-wound (constant rate) springs. This allows the rider to experience the same springing throughout the race — no surprises. Of course, road racing bikes typically ride on relatively smooth surfaces.

The reality is that springs are mostly there to hold the bike up at a correct height (setting the height is the function of preload) — it's the damping system's job to provide suspension control, and so is much more important to handling. A high-end shock absorber like an Ohlins, for example, has a similar spring to anyone else's, it's what's inside that counts.

Total Control.

RSS Feed

RSS Feed