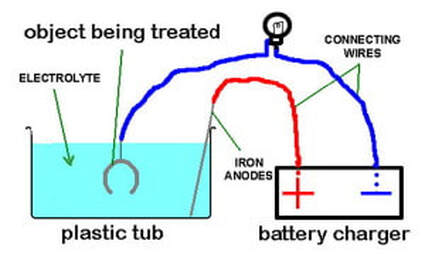

The process is simple, as seen in the diagram to the right. Direct current (12 volt) is passed through water causing rust to release from a negatively charged item to a positively charged piece of metal (anode).

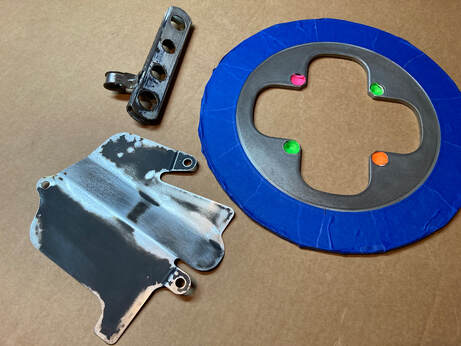

One tool I really wished I had room for in the shop is a media blast cabinet. That is the definitive means of prepping a piece of metal for paint, but media blasting can also affect the base metal's "complexion," while electrolysis will not. However, electrolysis will not remove dirt or paint and leaves a black discoloration which will need to be scrubbed or lightly sanded away. In any case, I wanted to give it a go with a few rusted bits from Project 39 — a rear brake rotor, torque arm, caliper mounting bracket and heat shield.

(Below) Here, I begin with the caliper bracket and snap ring. After adding warm water with a tablespoon per gallon of baking soda to form the electrolyte, I make the electrical connection. The close-up photo shows the telltale bubbling of the chemical reaction after only a few seconds. After about two hours of soaking, I removed the bracket from the brown, opaque solution and…success! The rusted spots were down to bare metal.

(click on images to enlarge)

If you're in a hurry, this is not your best approach — it can take 24 hours or even longer for severe rust removal, but for items like these, electrolysis can be a useful tool.

RSS Feed

RSS Feed