(click on an image to enlarge)

Next, I soaked any rusted steel parts in rust remover, then straightened the twisted brake lever in the vise and finally ground smooth several gouges on the shaft before sanding, painting and a fresh foot rubber. The chrome heat shield was polished as well as possible despite some rust pitting. Next came the labor intensive part — the footpeg and casting required hand sanding to remove any surface corrosion to get down to smooth aluminum. I elected to finish with 600-grit wet/dry paper to leave the surface with a brushed finish. All the small fasteners were detailed before final assembly and the aluminum parts were sprayed with two coats of Sharkhide to preserve the finish. While the assembly was off the bike I prepped and painted the black exhaust pipes for a finishing touch.

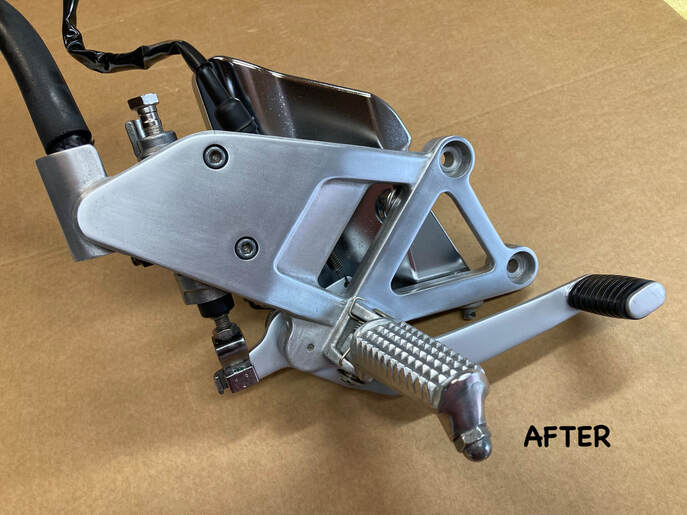

Below are some "after" photos — not perfect but a real improvement for this budget build.

RSS Feed

RSS Feed