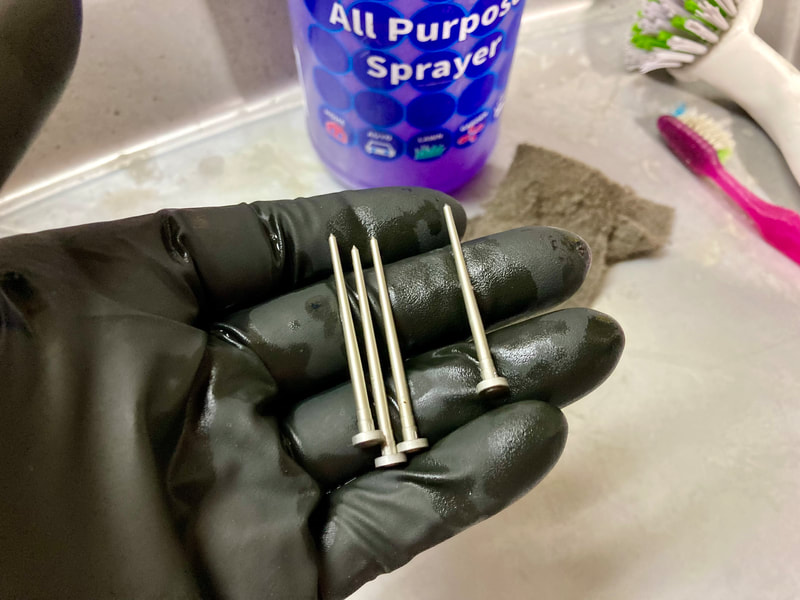

Carb parts fresh from a 'sonic bath

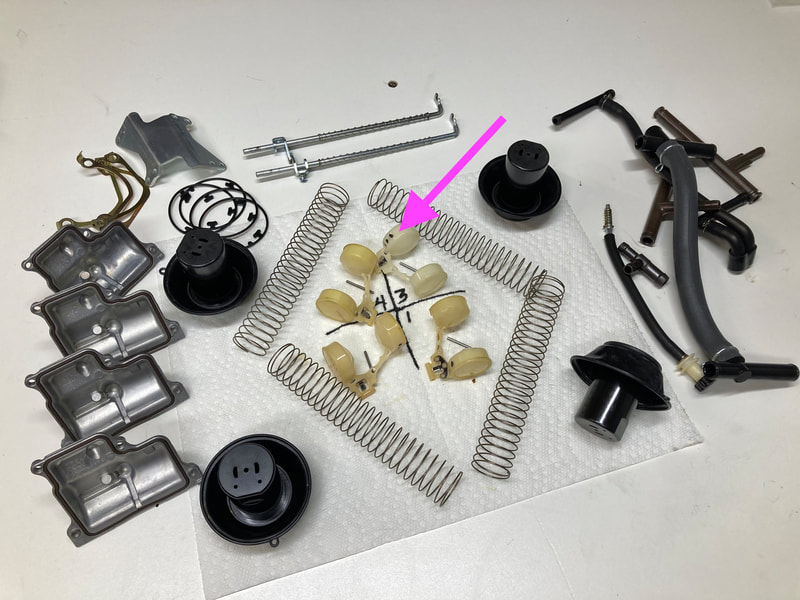

Carb parts fresh from a 'sonic bath (Below) These carbs' vacuum diaphragms are afflicted with some sort of white and green stuff, possibly mold or mildew? These slide assemblies are NLA so I treat them with a delicate touch. Here I'm using Zep degreaser, a mild cleaner, massaging the rubber diaphragm with finger pressure and a soft toothbrush around the edges. In extreme cases the round rubber edge can be coated with stubborn crusty corrosion from a rusted diaphragm cap — a challenge to remove without damaging the diaphragm. I use a warm soapy bath and a fingernail to gently scrape the crust off as best I can. If the rubber seems particularly dry I will rub on a thin application of red rubber grease to rejuvenate and preserve the rubber. I also clean the plastic slide by scrubbing with a non-scuff kitchen pad followed by a hot water rinse and air dry.

RSS Feed

RSS Feed