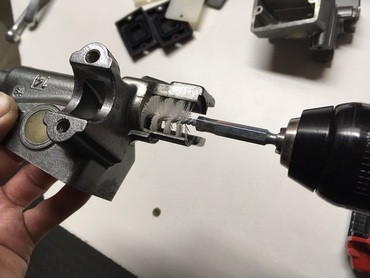

(A similar sleeve is found on the earlier VF calipers) (A similar sleeve is found on the earlier VF calipers) While refurbishing the brake calipers on Project 14 I came across an all-to-common issue — the lower mounting point on the rear caliper. The mount consists of this "sleeve," as Honda calls it, which is required to slide slightly to & fro in its boss as the brake is cycled. Trouble is, this particular pin is usually severely corroded and often frozen in place. The brake will still function but at a fraction of its potential. It seems well-protected by two tightly-fitted rubber boots (shown in background) but still suffers from its location at the bottom of the caliper.  This is the result of the sleeve being frozen in place. The inboard brake pad isn't allowed to slide freely, resulting in only the upper portion making contact with the disc. Note the bevelled profile of the pad. These pads are junk.  Fortunately, the sleeve and boots are still available from Honda. The sleeves retail for $10.85 and the boots for $3.85. The hard part is freeing the sleeve from the caliper — this one was soaked overnight in parts penetrator and twisted loose. The boots are often in reuseable condition.  The bore itself typically only needs cleaning with a brass brush and flushing with brake cleaner. I then coat the bore with some brake caliper grease and reinstall the sleeve and seals — there's a trick to this; install one seal, push the sleeve all the way through from the opposite side, install the second seal then slide the sleeve back to engage the second seal. I'm sure if these sleeves were serviced at each brake pad replacement or say, ten years, they'd remain in useable condition. Good to go! Let's mount 'em up. It was a case of what might have been. Way back in 1959 Ducati's U.S. importer, the Berliner Motor Corporation, convinced company management (and the Italian government, which had a stake in Ducati) to compete for police bike sales in America. Specifications required at least 1200cc and 16-inch tires, which would prove to be a major factor in the bike's failure to launch. None other than Fabio Taglioni, the eventual creator of Ducati's iconic L-twins, designed the 90-degree V4 for the new model — named Apollo for America's moon launch vehicles. The 1257cc engine put out an incredible (for the time) 100 hp which was more than overwhelming for both the brakes and tires. When testing revealed that current tire technology couldn't cope, the engine was detuned to 80 hp, which made the whole package non-competitive with Harley-Davidson and the British. The Italians pulled the plug. With a bit more development the bike could have been a contender and Ducati's future may have included many more cylinders.  Two Apollos and four engines were built and only one bike is accounted for. It belongs to a Japanese collector. Honda's other go-fast machine....  After 20 years (!) in development, Honda Aircraft's HA-420 business jet received FAA certification in 2016. I've been involved with airplanes since soloing at 16 and earned my pilot's license in 1991. I've followed Honda's progress with this unique and striking aircraft from the beginning. Honda's corporate focus in this world is as an engineering leader first and foremost. The company has decades of history filled with innovative consumer products but the HondaJet is surely the pinnacle. Aviation critics love the airplane. Flying magazine's January '17 issue honors the HondaJet with an Editor's Choice Award:

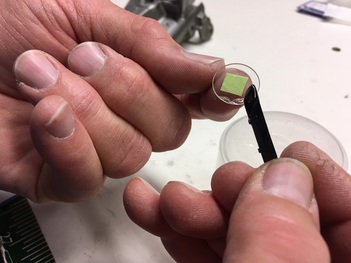

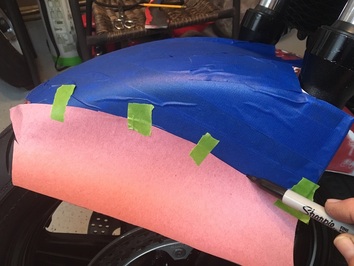

"As we can attest, the HondaJet flies beautifully and has the performance cred to satisfy its many buyers. Add it all up, and Honda has delivered a game-changing light jet that easily lives up to the hype." Congratulations to Honda on reaching this mile-high milestone. Project 14, an '87 VFR700 F2, needs attention lavished on all of its systems. When the clutch and front brake master cylinders were opened up here's what lay in wait.  This situation is very common with my projects and is due to nothing more than neglect. Brake fluid should be flushed every two years, and this is the long-term result of ignoring that maintenance item. I don't know how that solidified gunk forms, but fortunately it cleans up with a straightforward sudsy washing.  Both of these master cylinders will require a complete rebuild. That involves new seals and replacing the aged sight glasses. I like to clean the bore with solvent and a plastic rotary brush. If the bore then passes a visual inspection I move on with the sight glass repair before installing the new seals — I don't want to risk debris from the old sight glass contaminating the seals.  I begin with the demolition of the old plastic window. A tap with a small screwdriver from the inside starts the process. Then, using a larger flat-blade screwdriver I pry around the perimeter from the outside, working my around. Sometimes they come out pretty cleanly, as here, and sometimes not. When I come across a stubborn lens that just won't let go, I use a small wire brush on the Dremel tool to finish the job.  Due to manufacturing variances, the lens will sometimes be a bit too tight a fit. A few minutes spent gently sanding the edge, while rotating the lens, on some medium grit sandpaper will allow it to drop into place.  After a final cleaning of the lens and it's seating groove with acetone or similar, I stick the lens on a finger tip (using rolled-over masking tape) and carefully apply adhesive around the perimeter. I've used clear RTV but here I'm using Permatex 5-minute epoxy which claims to be impervious to most chemicals. And brake fluid is actually pretty nasty stuff. Put the lens place and secure with a rubber banded socket while the adhesive cures. Expect some residual adhesive to show, but overall a practical repair.  Now we're ready for the seal kit. I hold the assembled plunger down in the bore (against the spring pressure) with a screwdriver while inserting the circlip. The bent-tip snap ring pliers makes this a smooth operation. Be sure and coat the parts with brake fluid when installing. (clutch master shown) >>  All that's left are the levers. Motion Pro and probably others make complete reproduction levers for the VFR, but there's nothing like the originals if they can be saved. A thorough inspection is called for with these old parts and their unknown history. While looking over the brake lever I discovered this crack on the underside. It obviously resulted from a crash or tip-over. No question that this one goes into the trash bin. Fortunately, I had a NOS brake lever on hand.  Who knew these adjustable levers have so many parts? After a thorough cleaning, de-rusting and polishing, I carefully reassemble the levers with a touch of white lithium grease on all the rotating parts. Fresh stainless steel reservoir screws are a finishing touch. These master cylinders are ready for the next thirty years......  Project 14 is at the point where it's time to start considering the bodywork details. This is a mild custom build and as such I have more freedom to change up a few details. Like the front fender, for example. Honda's 80's styling cues include a visually "heavy" fender. Project 14 has a taller 17-inch front wheel and, to my eye, the fender will have a better aesthetic if it's "lightened" a bit. << OEM fender  To accomplish this I mounted up a fender from my stash and covered it in blue painter's tape. The leading edge curve is very critical for the right look, so, looking around the shop I grabbed the front fender from the Magna Project and traced out the trailing edge of that fender onto the VFR's leading edge. Perfect. Leaving the rear portion intact, I freehanded a few curves onto the tape until I found the shape that looked right to me.  With a medium-duty cut-off tool mounted up to the Dremel, I slowly began tracing the line for an initial cut, followed by two successively deeper cuts till the right half of the fender was away. I'm very careful to avoid any slips with the cutting wheel onto the "good" portion of the fender as that will require additional bodywork to repair.  Well, no turning back now, so on to the other side.  I could have attempted to freehand the left side but figured out a way to duplicate the cut. I traced the cut line onto heavy paper, turned it back-to-front, and taped it in place on the left side, tracing the edge onto the fender. Three passes with the Dremel and I had my basic shape. For the all important boy-racer effect I added some "lightening" holes to the rear portion. Three different drill sizes and Bob's your uncle. Project 14 will be sporting OEM red/white/blue body panels. My plan is to change the fender color from original red to blue, which will also help lighten the look. Honda used this trick with the 2007 VFR800 Anniversary Edition and it seems to make more sense, stylistically speaking. All that remains for this little project is to smooth the edges with files and sandpaper...and paint.

What: 1985 VF1000R

Where: North Texas Why: Unique, sorted, rideable, affordable Price: $5500 While cruising VFRdiscussion.com I came across this nicely-done restomod build based upon a VF1000R. Available in the U.S. only in '85-86, the R replaced the lower-spec F from '84. Neither bike was a market success here as they were eclipsed by the liter-class sports bikes of the day. Big sport-touring or "endurance" models just hadn't caught on yet in America. Which makes this model a great basis for modifying with some modern components while keeping the period look — a restomod. Here's some of the highlights: • Dynamag wheels front and rear • Aprilia triple trees and forks (Ohlins) • Huge Brembo brakes • Original taillight mounted in CBR900 tail & seat • M4 exhaust • Tarozzi rearsets • VFR750 fuel tank (gives the big VF a whole 'nother look) • Triumph Daytona 675 turn signals • 1986 headlights • Aprilia carbon fiber front fender • ...and many small touches and details The seller doesn't list his exact location. For more information visit his thread and contact him through the discussion board (registration required): http://www.vfrdiscussion.com/index.php?/forums/topic/84252-1985-vf1000r-restomod/& Online auction sites — online anything — can be a minefield. There's sometimes built-in safeguards or limited buyer protection, but in the end it's like everything else in life; buyer beware. I've been a frequent flyer in the eBay and Craigslist worlds since their beginnings and I've learned the hard way (more than once) that not everyone shares the same values as most of us. I once actually found a motorcycle seller online using my photos to represent his item. But beyond dodging the liars, thieves and scammers, there's still the old concept of just shopping around. Here's a few cases of current eBay listings for the same items at wildly disparate prices. (click on images for the links) Need a shop manual for your '90-93 VFR? On the left; $59.99. On the right; $9.99 How about a replacement brake lever? On the left NOS OEM; $12.28. On the right an aftermarket piece; $47.98 How about a steering head bearing kit? Amazingly, these items are the same brand, part number and from the same seller!! They even use the same photo. On the left; $29.40, on the right; $52.00.  Speaking of expensive parts, an Arizona seller is offering this nice '86 seat cowl for an optimistic $249.95. In my experience he should maybe be hoping for something closer to $150. Best of luck.  And here's a new OEM Honda hand grip. These are still available at your local dealer for about $12. Our seller's price is $16.47...plus $9 shipping!! Caveat Emptor.  What: 1989 Honda VFR400R (NC30) Where: Seattle, Washington Why: Your chance at a grey market rider Price: $9800 Bid, reserve not met Often referred to as the RC30's little brother, the VFR400R was never officially imported to the U.S. Produced from 1989-92, the NC30 was an evolution of the earlier NC21 & NC24. The NC30 was a scaled-down version of the RC30 and featured its single-sided swingarm, a 360-degree crankshaft, 18" rear wheel and 14,500 RPM redline. Our feature bike is represented as a 6000-mile original-condition example, with the exception of new brake rotors & repainted wheels. It's striking in the one-year only red/white/blue Japanese-market colors. Maintenance is up-to-date and this would be a great special occasion rider. The auction includes a link to a short YouTube video where we can hear that distinctive gear-drive cam "noise." Values are rising on these little VFRs — the listing indicates a $12,000 reserve. Is it worth it? We'll soon see, the auction ends Sunday at 8:00 pm. UPDATE: Sold...winning bid $11,200.  From the brothers Coppiello in Padua, Italy comes this stunning take on a new-age cafe racer based on a 1992 VFR750. Their shop, North East Custom, produces some exquisitely crafted bikes with a fine eye toward detail and style. The V4 is seldom chosen as a basis for a custom, but this one shows that in the right hands the result can be both beautiful and maybe a little practical. The mechanicals remain factory so this is a purely cosmetic custom. The stock fuel tank is integrated perfectly with the Guzzi-like quarter fairing and hand-made side covers and seat cowl. The period red, white and blue is perfect for this build and the white wheels a nice finishing touch. While most customs lack any pretense at utility, I'm betting this one would be as much fun on a Sunday morning canyon run as it would be to sit and gaze at in the garage, beer in hand. For the BIKEEXIF feature on this VFR, visit here. |

THE SHOP BLOG

|

RSS Feed

RSS Feed