This situation is very common with my projects and is due to nothing more than neglect. Brake fluid should be flushed every two years, and this is the long-term result of ignoring that maintenance item.

I don't know how that solidified gunk forms, but fortunately it cleans up with a straightforward sudsy washing.

Both of these master cylinders will require a complete rebuild. That involves new seals and replacing the aged sight glasses.

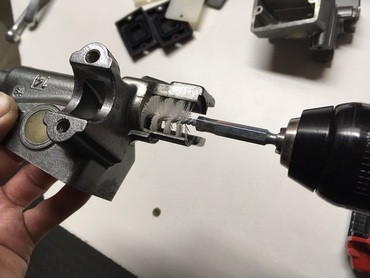

I like to clean the bore with solvent and a plastic rotary brush. If the bore then passes a visual inspection I move on with the sight glass repair before installing the new seals — I don't want to risk debris from the old sight glass contaminating the seals.

I begin with the demolition of the old plastic window. A tap with a small screwdriver from the inside starts the process. Then, using a larger flat-blade screwdriver I pry around the perimeter from the outside, working my around.

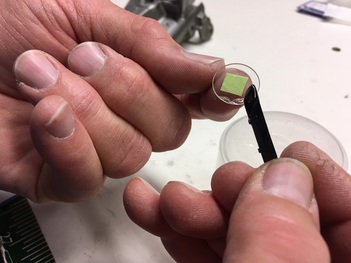

Due to manufacturing variances, the lens will sometimes be a bit too tight a fit. A few minutes spent gently sanding the edge, while rotating the lens, on some medium grit sandpaper will allow it to drop into place.

After a final cleaning of the lens and it's seating groove with acetone or similar, I stick the lens on a finger tip (using rolled-over masking tape) and carefully apply adhesive around the perimeter.

I've used clear RTV but here I'm using Permatex 5-minute epoxy which claims to be impervious to most chemicals. And brake fluid is actually pretty nasty stuff.

Put the lens place and secure with a rubber banded socket while the adhesive cures.

Now we're ready for the seal kit. I hold the assembled plunger down in the bore (against the spring pressure) with a screwdriver while inserting the circlip. The bent-tip snap ring pliers makes this a smooth operation. Be sure and coat the parts with brake fluid when installing.

(clutch master shown) >>

A thorough inspection is called for with these old parts and their unknown history. While looking over the brake lever I discovered this crack on the underside. It obviously resulted from a crash or tip-over. No question that this one goes into the trash bin. Fortunately, I had a NOS brake lever on hand.

Who knew these adjustable levers have so many parts?

After a thorough cleaning, de-rusting and polishing, I carefully reassemble the levers with a touch of white lithium grease on all the rotating parts. Fresh stainless steel reservoir screws are a finishing touch.

These master cylinders are ready for the next thirty years......

RSS Feed

RSS Feed