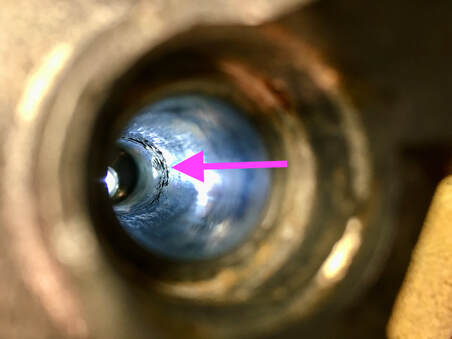

I rarely break my personal rule of inspecting every component, but I made an exception with Project 31's clutch hydraulics. While cleaning and inspecting the master and slave cylinders I could see that fresh overhaul kits had been installed sometime in the not-to-distant past, so I let them pass. My mistake, as disassembly of the clutch master revealed a ring of corrosion in the bore (pink arrow in this photo). The rubber seal can't hold an effective seal at this point in its travel, hence the leakback causing the creeping clutch engagement. I can't hone or otherwise repair this tiny aluminum bore, so a replacement master is required.

I had a feeling that I should open up the clutch slave for a closer inspection as well. Good thing I did. The assembly was clean and there was, in fact, fresh seals installed…but the main seal was installed backwards! Amazingly, it functioned that way, but come on…even the Factory Service Manual clearly pictures the correct orientation. I can't trust the used seal, so a fresh one was fitted.

Yet another reminder to always verify someone else's prior work.

In this case I was able to simply wipe clean the empty bore, refit the piston with its new seals, and bolt the assembly back onto the engine. Quick and clean.

RSS Feed

RSS Feed