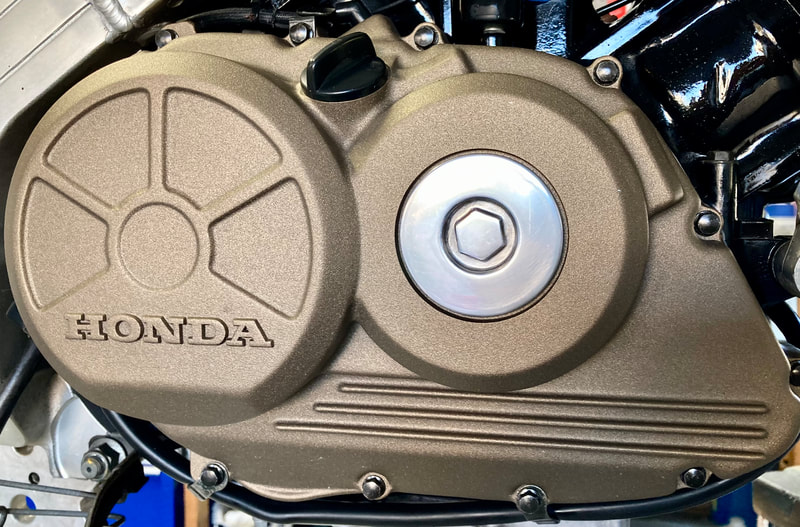

Let's go through my part of the process to get to the finished product, beginning with disassembly.

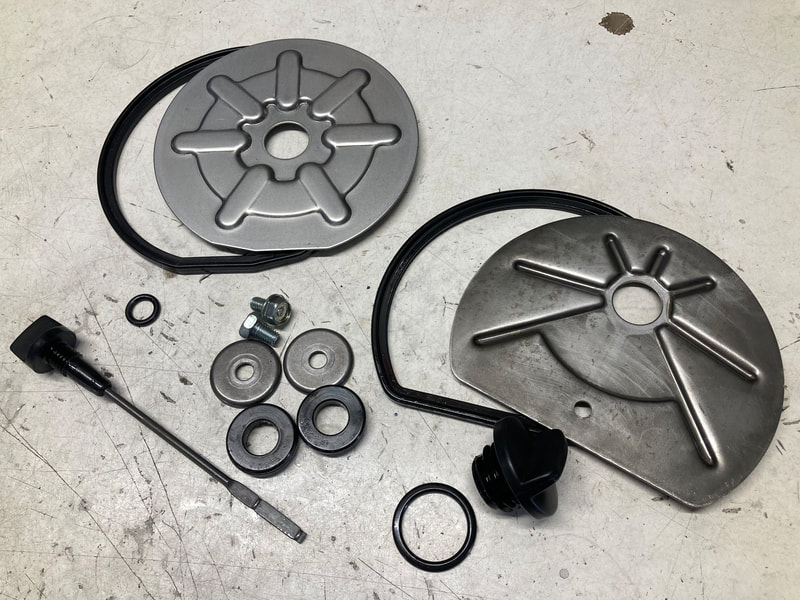

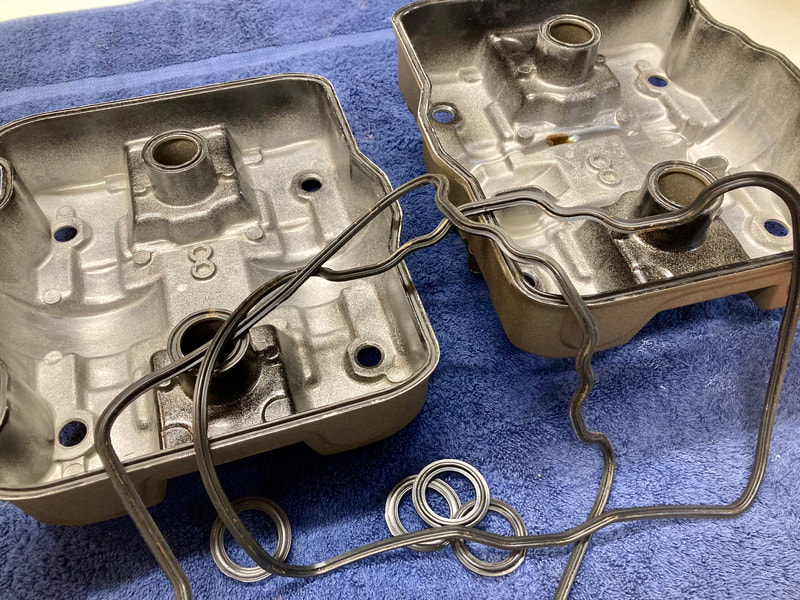

Powdercoating requires media blasting and baking in high heat, so everything must be stripped from the assemblies. For the clutch/alternator covers, this begins with removal of the (sound?) baffles on the backside of the covers. A single bolt holds each plate and its rubber gasket, which are lock-tighted in place, requiring an impact tool for removal.

(click on images to enlarge)

Once stripped down to the bare covers, I address any cosmetic damage. In this case only the lower portion of the alternator cover had some road rash. I smooth out the metal with a combination of light sanding discs on a die grinder followed by hand sanding till smooth.

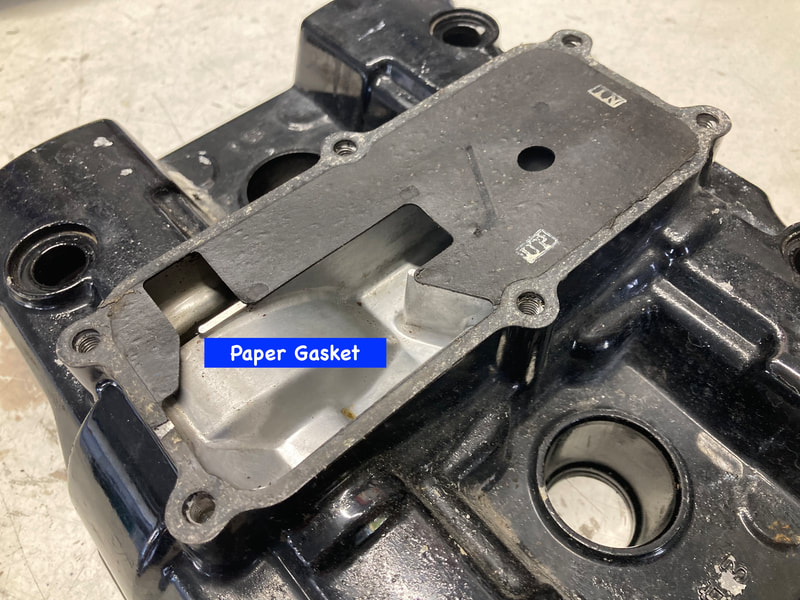

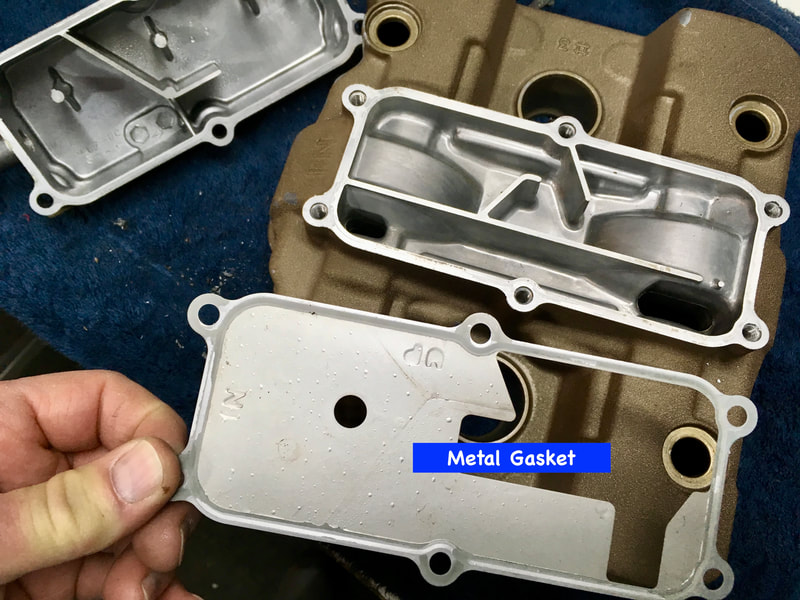

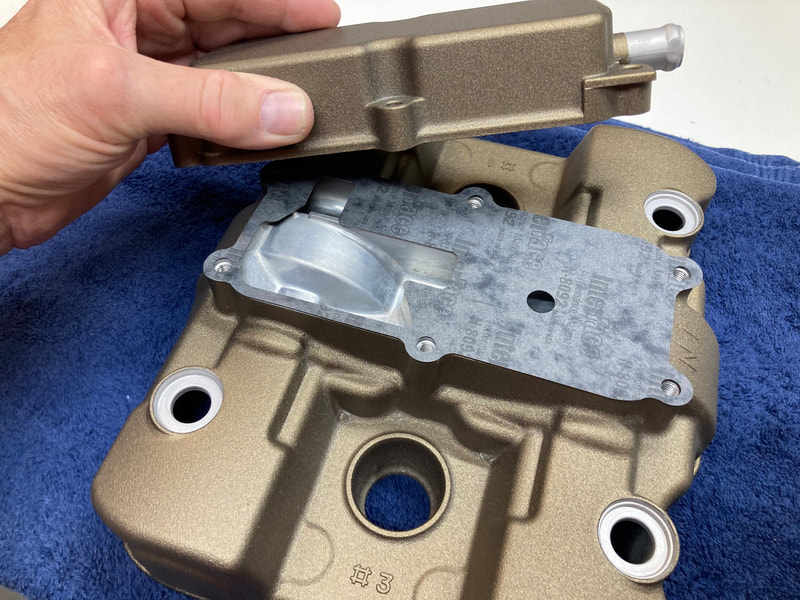

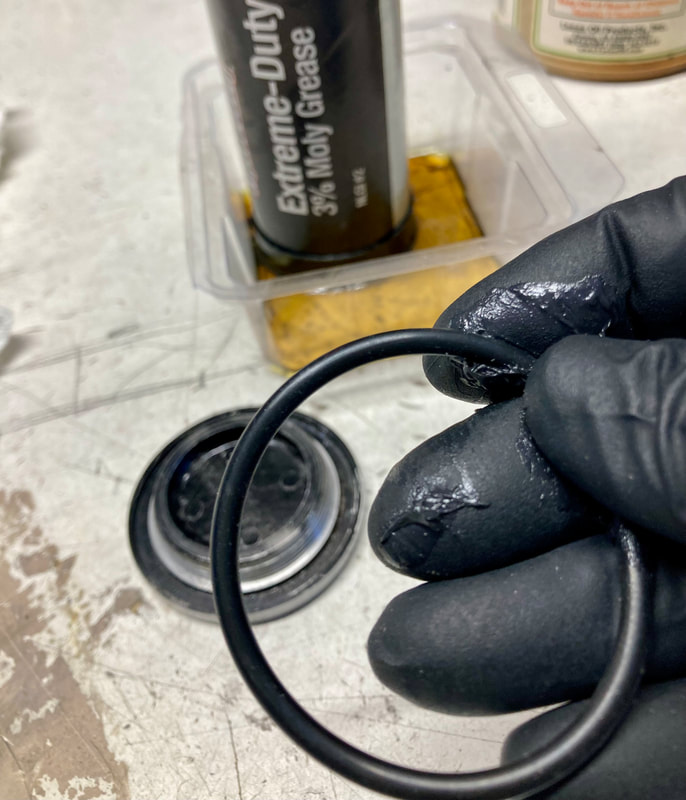

The manual also states, "apply sealant around the projections of the gasket." I have no idea what they're referring to, but I've never had a reused valve cover gasket leak when installed dry. YMMV.

RSS Feed

RSS Feed