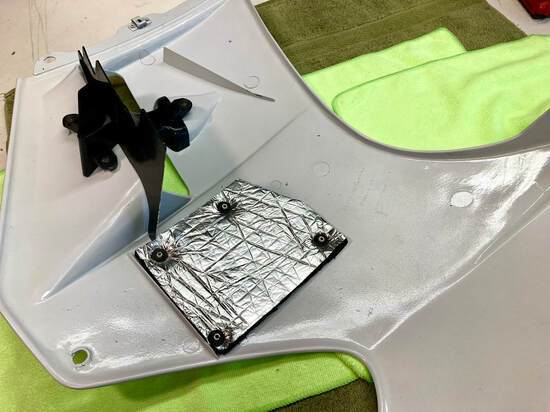

(Below) I begin with a paper template, cut to shape, and punch out the fastener holes with a hammer and homemade punch. Those spring clips are difficult to remove (gently but forcefully pull upward with a pliers) and sometimes the plastic pegs they attach to break off. No worries, between the remaining pegs and the sticky backing, the new pad will be secure. Here, the center peg is missing.

While I'm at it, I'll need to refurbish the fairing stand-offs. These came in two styles for the 2d-gen bikes; these elegant billet aluminum posts the more common. They were originally black, but we've decided to brighten them by going with the polished aluminum look.

Trouble is, that black can be either paint or anodize. We had one of each, so I would first need to remove the anodizing. I do this by soaking the item in spray-on oven cleaner for about 30 minutes in the warm sun followed by a rinse with water. Next, I screw an allen bolt into the open end to allow chucking in a hand drill, then polish with a strip of wet/dry sand paper, 400 to 800 grit, depending upon the condition of the aluminum finish. A quick hand or wheel polishing completes the process. I like to coat the finish with Sharkhide sealant to preserve the shine.

RSS Feed

RSS Feed