The forks were in need of new seals, but the rest of the internals look almost new, as befits a 10,000-mile example. The repainted front wheel is reassembled with fresh bearings and new Bridgstone BT45 and is ready for mounting. Steering head bearings feel great so I'll just do a simple adjustment.

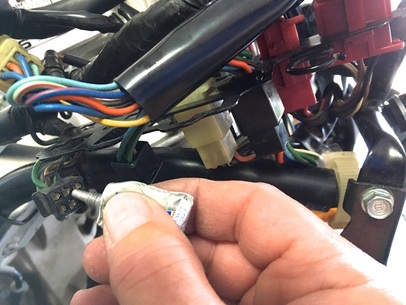

Lots of connections...

Lots of connections... I visually inspect all the connectors, clean with plastic-safe electronic cleaner and apply di-electric grease. Despite its name, this special grease is actually non-conductive, which is a good thing — it could otherwise cause shorting across these tiny terminals. Instead, its function is to prevent corrosion by helping to keep moisture at bay. I spend hours on this chore.

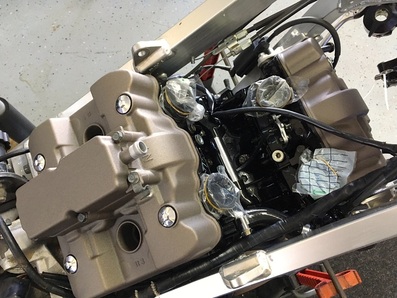

Next up, detailing and installing the radiator.

RSS Feed

RSS Feed