One of the most critical but often most neglected systems on a motorcycle. When you add in old age and long periods of disuse, well, your brakes will pay the price. Such is the case with the calipers on Project 16. One of the brakes were dragging, indicating worn caliper seals, so a rebuild for all three calipers is in order.

The seals are small rubber o-rings, actually square section, two per piston and serve not only as a means to protect the precious brake fluid by sealing out the elements but also act as a mechanical spring, deforming as the piston is forced out during braking and then pulling back very slightly on the piston when pressure is released, allowing the brake pad to release its hold on the disc. The seals may look simple but are precision items and should be treated as such. They're still available from Honda and aftermarket suppliers, like K&S, for about $20 per caliper.

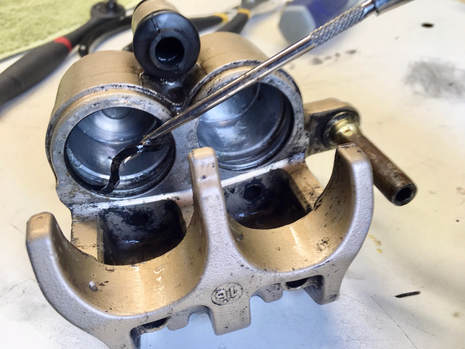

Using precision shims cut from the finest paint stir sticks, I begin removal with a full stack of shims, removing one at at time (alternating with pressure) till the the final shim has the pucks equally near their exit point. The final blast of air or hydraulic pressure will force out one of the pucks, leaving the second one to be removed manually. BE VERY CAREFUL DURING THIS FINAL PUSH. If you're using air pressure the piston can shoot out of the bore like a bullet, ricocheting off you or the shop walls, damaging itself or anything in its path, including you. If you're using hydraulic pressure the brake fluid will projection vomit the fluid everywhere. Just one of the many joys of playing with old bikes.

Next I use a dental pick and carefully extract the seals. The next steps are cleaning, inspection and reassembly, but you're through the tough part.

RSS Feed

RSS Feed